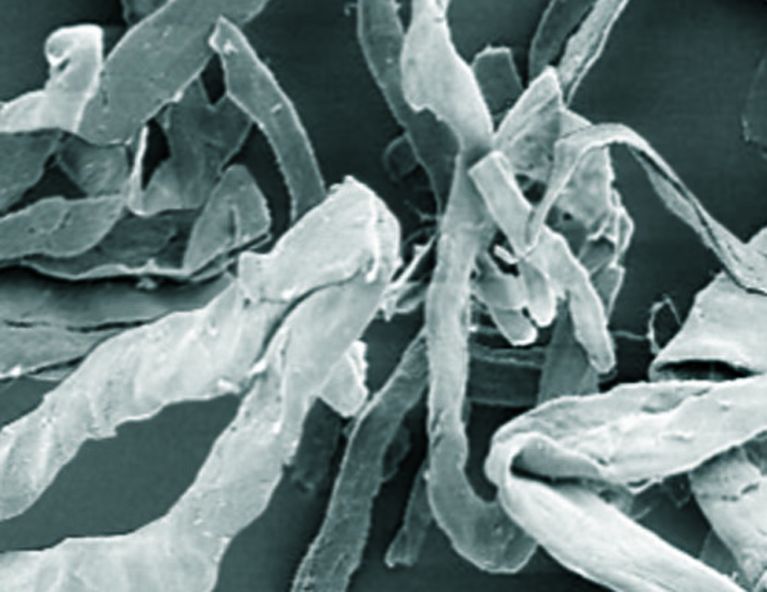

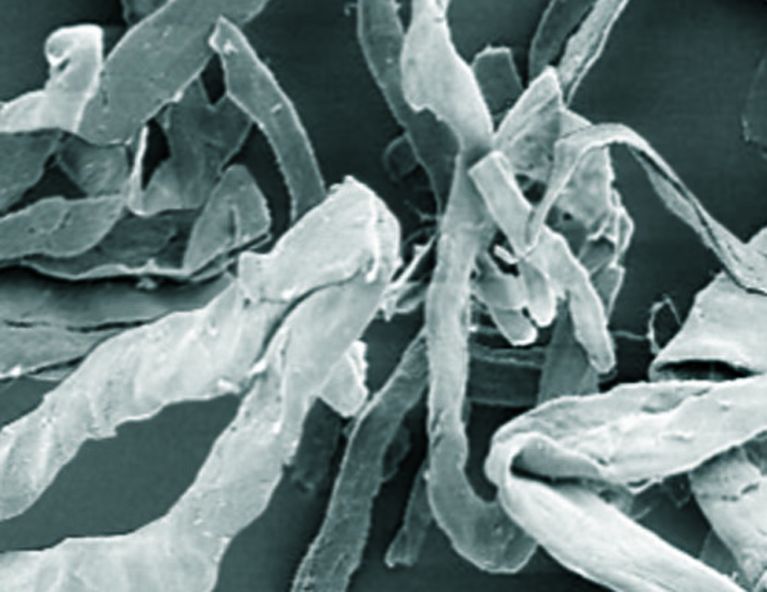

Cellulose

Available as natural wood fibers, extract free fibers and highly pure fibers for food and pharma applications

Filtration's Finest

The LENZING CakeFil system is a process candle filter for cake building filtration with slurry or dry discharge. Its patented system enables highly efficient backwashing, thereby extending the service life of the filter fabric.

Advantages

Technical data

| Possible max. configuration (depending on customer requirements) | |

|---|---|

| Flow rate | > 1000 m³/h |

| Operating temperature | 110°C (higher possible upon agreement) |

| Solids content | 10%w |

| Area of application (viscosity) | Filtration of low to medium viscosity media |

| Flux (throughput per filter surface) | 4 m³/m²h |

| Filter surface wet discharge (per filter) | 356 m² |

Available as natural wood fibers, extract free fibers and highly pure fibers for food and pharma applications

Agglomerated fossilized residues of diatoms

Volcanic material used in chemical and food industry

For removal of hydrocarbons, chlorine or

other unwanted dissolved components

by adsorption

Further product information

The LENZING CakeFil system enables true process automation without downtime or manual operation. Its high-quality material designs allow it to be used in a wide variety of industries and applications.

FAQs and contact

Innovation Flows